Not known Details About forklift lights safety

Not known Details About forklift lights safety

Blog Article

Regardless of what forklift lights may very well be mounted, operators should conduct a each day Check out Should you have any of these lights mounted with your forklift. OSHA might not demand you to have them, but when you are doing, they need to be working adequately.

Blue safety lights are really valuable when navigating via slim aisles mainly because their distinctive blue illumination grabs the attention of people close by, alerting them on the forklift.

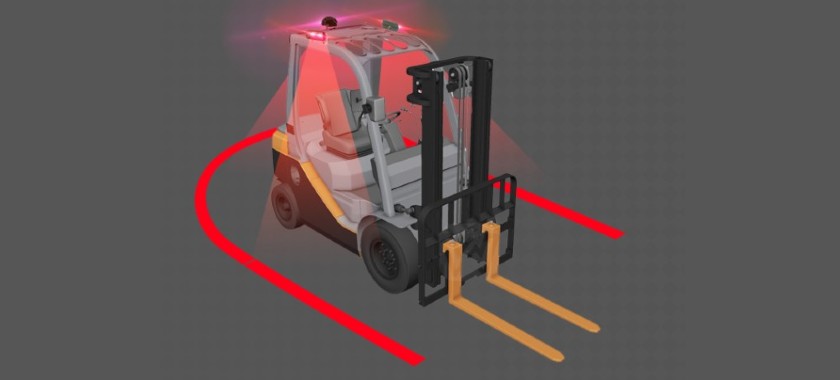

The forklift laser safety lights supply a specific Visible reference for operators by indicating the exact route the device's wheels will traverse. This characteristic facilitates specific forklift positioning, assists in steering clear of road blocks, and enhances navigation in confined Areas.

Lack of communication can result in injury and death when handling equipment. But, you are able to avoid accidents by training your staff members on forklift hand indicators.

Most forklift motor vehicles have pre-drilled holes for mounting warning lights and work lights. You can also find safety lights out there that come with brackets that can easily attach into the forklift. Those kinds of lights want no drilling.

Strobe lights, blue spotlights, and crimson facet lights on a forklift are not essential by OSHA, but introducing these lights will help aid good safety procedures in certain function environments, and so are frequently meant as an method or warning gentle.

When the operator reverses the forklift, the blue gentle shines on the ground behind it, eradicating any confusion in regards to the equipment’s trajectory.

If pedestrians and operators only look at the floor for lights, They could miss warning indicators and Seems all-around them.

Would you prefer to Have a look at the car information and testimonials We now have meticulously chosen and revealed for you personally?

Very clear interaction: Warning lights converse crucial information to These all-around them. One example is, a flashing red gentle could suggest the forklift is carrying a major load which is going to reverse. This conversation assists others foresee the actions of your forklift and change their behaviors.

Therefore, immediately addressing mechanical challenges is essential for stopping incidents just before they occur and holding forklift operators and those close by Risk-free. Forklifts are applied often in chaotic environments, so keeping safety while running forklifts is paramount.

forty% of forklift lights safety all forklift accidents contain a pedestrian. Guarantee pedestrians stay a secure distance clear of the forklift Together with the Red Zone Warning Light-weight. The Crimson Zone puts a shiny crimson line on the ground, near the forklift lights safety forklift, to point out pedestrians in which they don't seem to be permitted. This zone will also be called the HALO zone and will forklift lights safety be adjusted to the space within your selection. The Pink Zone assists protect against foot injuries and collisions from rear conclusion swing, in addition to, exhibiting the NO GO ZONE around any piece of cell forklift lights safety gear. How will be the Purple Zone mounted, wired up and altered? The Crimson Zone lights are mounted to the perimeters of your forklift and may also be mounted to the rear and/or front. A single Purple Zone light-weight is required for both sides in the forklift you should protect. They include a Resource free bracket to be able to speedily and simply mount them towards the forklift’s overhead guard with no modifying or harming it in almost any way. Our Purple Zone online video reveals the complete mounting procedure. They can be mounted a little in again of where by the operator sits In order never to interfere with their development as they get on and from the forklift.

Just about every automobile requirements frequent checkups and repairs periodically. It’s only standard that forklifts need this sort of attention as it's forklift lights safety its

A halo zone refers to your scheduled place all over a forklift that is certainly marked by a visible indicator, like a painted line or striping.